Solutions

Digital Twin solutions for your digital enterprise

Digital Enterprise suite digitizes entire supply chain which includes Product Design, Process Planning, Process validation, Production Planning & Execution and Product services.

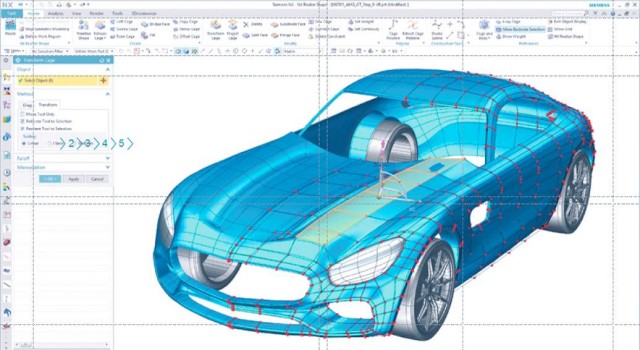

Digital Twin Product – Product Design

Product design engineers leverage the latest and greatest CAD solutions (AutoCAD, Siemens NX, Dassault Catia, Solid edge, Solid works… ) to create 3D CAD Models or Products. Multiple versions of data are created, managed, verified and changed throughout the product design lifecycle. Effective Product Data management (PDM) Solutions (Siemens Teamcenter, Dassault Enovia, ARAS, and many web based PDM systems) play a critical role in streamlining the Product Design process to build a Digital Twin Product.

Digital Twin Product solution modules:

- Requirements Management

- Program/Project Management

- Product Data Management

- BOM Management

- Change Management

- Process Workflows

Digital Twin Production - Process Planning

The Digital Twin of Plant/Factory, Digital Twin of Tools and Resources along with Digital Twin Product helps create a detailed Digital Twin Production Process Plan with sequence of operations and validate and build most optimal Production scenario.

Digital Twin Production solution modules:

- BOM Management

- Plant Management

- Resource Management

- Process Planning & Routing

- Process Simulation

- Time Management – MTM

- Logistics Planning

- Line Balancing

- Plant Simulation

Digital Twin Performance – MOM / MES

MOM / MES (Manufacturing Operations Management / Manufacturing Execution Systems) are used to represent factory operations. Digital enterprises have connected the shop floor with Industry4.0/IIOT devices. Now the data is continuously transmitted and analysed using the Machine learning /AI algorithms to identify and rectify any failures immediately to improve productivity.

Digital Twin Performance solution modules:

- Production Schedules

- Detailed Line Balancing

- Time Management – MTM

- Logistics Schedules

- Industry 4.0 / IIOT sensors & systems

- Machine Learning Solutions

- Reports / Dashboards

Digital Maintenance Services – MRO

Industry 4.0 / IIOT devices are helping OEMs to build products with integrated automation systems. These IIOT systems continuously transmit the key parameters of the product usage to remote diagnostic centres. These centres are equipped with Machine learning / AI algorithms to generate preventive & predictive maintenance plans and request. Helping services departments to improve serviceability and increasing customers productivity.

Digital Maintenance solution modules:

- Industry 4.0 / IIOT sensors & systems

- Machine Learning Solutions

- Service Management Systems

- Workflow Process Management

- Product Digital Twin

- Reports / Dashboards